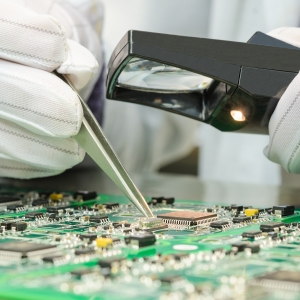

At DERF, our goal is to establish a long-term relationship with each of our customers. That’s why Quality Assurance is so important to us.

We have spent years developing procedures that address a complete range of quality concerns. From the quality assurance checks performed on the all the product we receive, through our state-of-the-art packing and shipping process, we guarantee that only the best gets delivered to our customers.

Our in-house Technology & Capabilities include:

- Quantity Verification: VJ Electronix XQuick2 plus

- Visual Inspection: Keyence VHX 7000N Digital Microscope up to 2000x magnification

- Dimensional Inspection (non-contact): Keyence VHX 7000N Digital Microscope up to 2000x magnification

- XFR Lead Finish Evaluation (RoHS, non-RoHS): Fischer Scope X-ray XDAL

- Decapsulation: Chemical – Nisene JetETCH PRO, Thermal – Paragon Kiln

- Solderability Testing: MUST System 3 Force curve.

- Advanced Surface and Lead inspection: Hitachi TM4000Plus Scanning Electron Microscope

- Surface test Remarking: Mineral Spirits + Isopropyl Alcohol

- Surface test Resurface: Acetone

- Surface test Heated Solvents: 1-Methyl 2 Pyrrolidone

- Surface test Heated Solvent: Dynasolve 750

- Passive component basic functional testing

- Component baking and packaging according to J-STD-033D